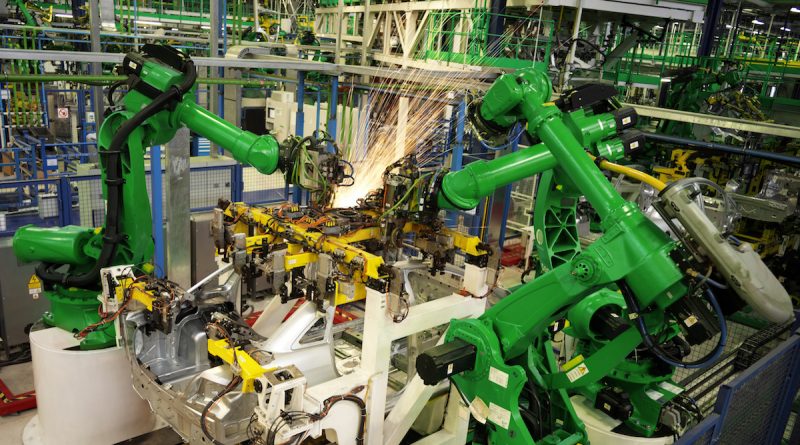

How to build a Smart Factory

How to build a Smart Factory – The smart factory offers a lot of untapped opportunities for manufacturers. In its 2017 report Smart Factories: How can manufacturers realize the potential of the digital industrial revolution, Capgemini highlights the potential of the smart factory – it could add $500 billion to $1.5 trillion in value-added to the global economy in five years.

Digitizing manufacturing processes is not as simple as connecting devices to Wifi. For one, the manufacturing industry is historically known for a mechanical marriage of oil and steel to make moving metal parts — not so much cloud computing nor cyber-physical systems -M. Grenacher, Forbes

Let us start from the very beginning. How did the idea of the smart factory come to life?

Defining the smart factory...

Everything started with Industry 4.0 – the fourth industrial revolution. It is no longer just a buzzword but is, in fact, changing industries. The aim of Industry 4.0 is to make manufacturing agile – lower operational costs, improve product quality and speed up innovation.

Its main advantage lies in the flexibility it offers – stakeholders can work together in real-time benefiting from the connected systems. The constant stream of data coming from connected systems enables quick learning and adaptation to new conditions. Stakeholders can predict when a certain event is about to happen rather than simply react to it. Thus better decisions are made which ideally results in higher productivity.

The smart factory concept is developing rapidly, so it is impossible to put a final definition to it. According to Deloitte Insights “the smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes.”

A little glimpse of smart manufacturing is the WORKERBASE system. It optimizes manual work by coordinating work processes in a better way. At the same time, the system collects numerous new data points, providing the basis for self-adapting and self-learning systems. A stepping-stone towards the smart factory, as defined above, is the collection of data from the interconnected system, analyzing it and using it to enable self-optimization.

Data is at the heart of the smart factory. Collecting data from manual work processes leads to a better understanding of actual workflows on the shop floor and makes it easier to organize processes in an agile way. One of the best-known scenarios being discussed when talking about the smart factory is “predictive maintenance”. Maintenance takes place at the very moment it is needed and production standstills can be avoided thus reducing costs. In addition to that, analysis of operational data leads to better allocation of production resources avoiding idle states.

Enabling the smart factory

What benefits does this bring? Here are some of them:

- improved product quality and utilization

- reduced downtime and cost

- increased safety and efficiency

Having in mind all the benefits, it is clear that enabling the smart factory becomes a high priority for the majority of manufacturers. The Capgemini report revealed that “though 76% of manufacturers either have a smart factory initiative that is ongoing or are working on formulating it, only 14% of companies are satisfied with their level of smart factory success.”

How can companies enable smart factory initiatives successfully? There is one factor which is critical to enabling the smart factory – the level of digital maturity. A Capgemini survey found out that “98% of digital masters have established a roadmap for their smart factory initiatives, compared to 41% of beginners. We have seen that digital masters are reaping the rewards of this structured approach.”

Assessing the digital maturity of your organization and acting accordingly is extremely important for building the smart factory (figure 1). Reaching the desired digital maturity level can be critical to the success of your smart factory initiative.

Figure 1: Digital maturity of manufacturers. Source: Capgemini

Having prepared a solid base – a high level of digital maturity – here is what comes next. According to the Factory Optimisation Solution Brief, published by Dell IoT Solutions, there are four pillars for achieving IoT-enabled smart factory optimization:

- Connectivity: Determine required data – collect and curate relevant data across systems.

- Cloud: Accelerate implementation via cloud data centers – provide a secure and flexible environment.

- Analytics: Apply advanced analytics to manufacturing data – assess equipment performance.

- Application Development: Accelerate innovation – deliver faster with agile software development solutions.

How to achieve all this? Actually, starting small and learning valuable lessons in a manageable environment, can be an effective solution. Once lessons have been learned, scaling can be done to additional factories and production lines (figure 2).

Figure 2: Scaling to unlock value. Source: Deloitte analysis

Where to start when you are not sure how to start implementing a smart factory initiative? Give it a try with the WORKERBASE starter kit and get a demo – focus on a single use case at one production line. For example, with an Alarm app or Support call app. Starting small is the perfect way to explore the possibilities of smart manufacturing and grow over time once you are ready to scale. Read more about the guiding principles of the smart factory.

Source: workerbase

Title Photo by Ant Rozetsky on Unsplash