Apple shores up Vietnam supply chain

|

| Apple shores up Vietnam supply chain, illustration photo |

Pegatron, a major Apple manufacturer with facilities across the globe, last Monday got the nod from Taiwanese leaders to inject an additional $101 million into Vietnam. The group had already announced plans to invest up to $1 billion into the country.

The Taiwanese company will fund three high-tech production factories in the northern port city of Haiphong. Pegatron secured an investment certificate for the $19 million facility in March last year.

The company is expanding its second project with capital of $481 million to make computers, electronic devices, communications equipment, electronic components, and circuit boards for global tech giants.

The third project, worth $500 million, is slated for the 2026-2027 period. Pegatron also plans to relocate its research and development (R&D) centre from China to Vietnam.

Other Apple suppliers like Foxconn and Wistron are also following suit, and already employ hundreds of thousands of workers in Vietnam.

Reza Akbari, senior programme manager and senior lecturer of Logistics and Supply Chain Management at RMIT University, said that Vietnam boasts several important factors for such reallocation. Since the US-China trade war began there have been discussions over moving suppliers from China to Vietnam. Additionally, significant supply chain disruption caused by the COVID-19 pandemic has boosted the number of Apple suppliers relocating to Vietnam in particular.

According to the General Statistics Office of Vietnam, adaptability and resistance have been the key factors of Vietnam’s economic recovery, especially in the first quarter of 2021.

“Apple’s supply chain is on the search to reduce its over-reliance on China in the aftermath of COVID-19 and Vietnam has significant potential for growth as a global centre for manufacturing, such as the opportunities arisen by free trade agreements and the newly-approved funding by the Taiwanese government,” Akbari said.

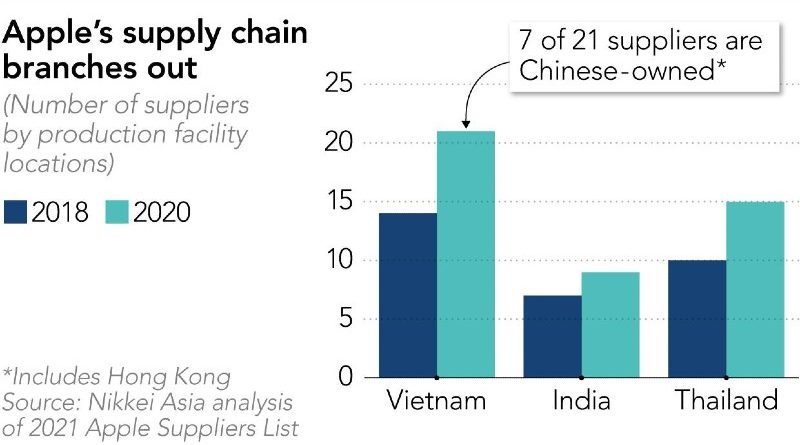

Indeed, Apple increasingly used more suppliers from Vietnam last year than it had done two years ago. According to the latest Apple annual supplier list, the tech company had 21 suppliers in Vietnam in 2020, higher than the 14 in 2018.

Some notable names in the list include Compal Electronics in the northern province of Vinh Phuc, GoerTek and Samsung Electronics in the northern province of Bac Ninh, Foxconn and Luxshare Precision in the neighbouring province of Bac Giang, LG Display and LG Innotek in Haiphong.

The number of Apple suppliers began to increase in Vietnam as soon as the trade war began. Seven of the 21 are owned by Chinese or Hong Kong-based companies, which include AirPod assemblers Luxshare and GoerTek, both of which have been producing the wireless earbuds in Vietnam since early 2020.

Nguyen Manh Hung, a lecturer of Logistics and Supply Chain Management at RMIT University, stated that the entry of electronics giants like Samsung, LG, and Microsoft has created a new supply base that matches the current global demand of mobile and electronics parts, but at the same time enhances competitive pressures for the early entrance.

Samsung has already built its second-largest TV screen and home electronics factory globally in Vietnam, with the total investment capital of $2 billion. It has also invested $220 million in a new R&D centre in Hanoi.

Hung noted that Apple has been a big help to the growth of the Chinese and Taiwanese electronic industries over the last few decades. It could be good timing for Apple to show “a helping hand” to Vietnamese supporting industries since many global brands, such as Samsung and LG, have already set up their strong influence on this young and dynamic development.

By collaborating with Apple’s network, which is famous for strict quality standards, he believed that Vietnamese suppliers have been steadily improving their capacity to make it into the production chains of other global companies. The subsequent benefits in education and social development can be significant.

“Meanwhile, the reallocation of these suppliers would require approximately thousands of industrial and logistics engineers to supervise more than thousands of line employees responsible for assembling iPhone products,” Hung stated.

The growth of Vietnam’s suppliers on Apple’s official list also reflects Vietnam’s efforts to contain the pandemic. Although the latest resurgence of positive cases poses a threat to disrupt manufacturing activities of Apple-certified factories in the north of the country, Vietnam is once again on the right path to tame the pandemic.

Specifically, virus hotspot Bac Giang, which is home to Apple partners Foxconn and Luxshare, allowed half of the businesses based in its industrial zones to resume operation last week. The goal is to keep the tech supply chains going as many businesses in the zones are key global suppliers.

Source https://vir.com.vn/