Smart factory market will cross over $150B by 2025

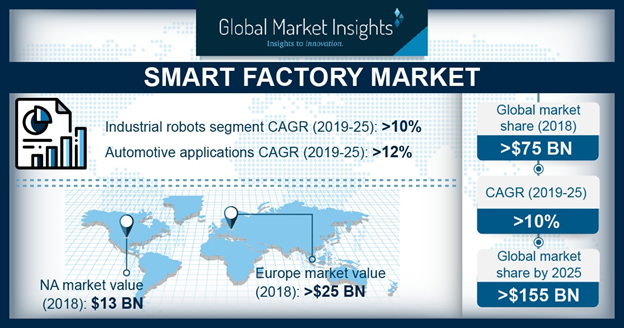

Smart factory market will cross over $150B by 2025 – Global Smart Factory Market is set to grow from its current market value of more than $75 billion (€66 billion) to over $155 billion (€138 billion) by 2025; according to a new research report by Global Market Insights, Inc.

The smart factory market is driven by the growing demand for intelligent industrial solutions that organize output and save huge labor & operational costs. These factories are digitally advanced & connected facilities that enhance the manufacturing performance along with replacing human workers in a variety of operations. Several technologies including IoT, AI, big data, and analytics in the smart factory market have the ability to operate autonomously. and correct by itself.

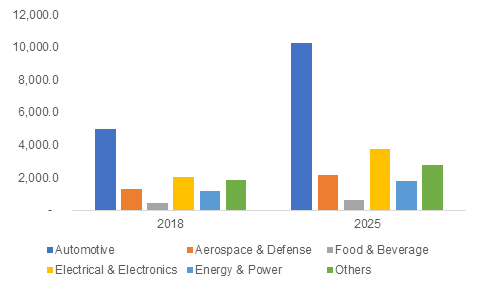

Various planning & management software detect probable errors and alert managers to eliminate losses, creating a high demand for these solutions. Additionally, government initiatives & policies in the European and Asian countries to promote the utilization of intelligent factory techniques are also major factors attributing to smart factory expansion. The industry is witnessing a high demand from the automotive, pharmaceutical, food & beverage, etc. applications owing to the popularity of cost-effective and automated benefits.

Machine vision components are witnessing an increasing demand in the smart factory market owing to the improved quality & consistency in manufacturing operations. Reduced manufacturing & operational costs due to the requirement of less labor for running equipment and process monitoring benefits industries, driving the market growth.

With the integration of vision components with production machines, the assembly, testing, and inspection functions can be performed in less space, reducing the overall footprint. These systems aid production teams & managers to perform intricate & complex tasks with high speed & precision, creating smart factory market solution demand. The machine vision cameras are increasingly deployed in intelligent factories due to high resolution and inspection advantages compared to traditional methods.

Distributed Control Systems (DCS) in the smart factory market is gaining popularity due to flexibility & simplicity advantages in controlling, monitoring, and reporting processes. These systems control complex enterprise processes, which are distributed throughout the entire system.

The controlling and redundancy features in DCS enhance the system availability & reliability, creating several market development opportunities. The industry players are launching new distributed control systems for applications in various manufacturing sectors. For instance, in March 2019, ABB announced the launch of its new distributed control system 800*A 6.1 that provides flexible & efficient engineering solutions.

In the smart factory market, automotive applications will grow at over 12% CAGR from 2019 to 2025 due to the transformation of automobile manufacturing facilities by adopting automated & robotic technologies. The Asian automotive industry is witnessing increased adoption of intelligent solutions such as asset management, enterprise resource planning, etc. to gain high productivity and reduce labor costs.

Major automotive manufacturers are transforming their production facilities with industrial robots that perform several manufacturing-related tasks with high efficiency compared to human labors. The OEMs are collaborating with software & service providers for building intelligent manufacturing units and gain IIoT benefits. For instance, in April 2019, BMW and Microsoft Corporation announced their collaboration to develop the Open Manufacturing Platform (OMP) that will include an open framework for intelligent technologies.

The Europe smart factory market was valued at over US$25 billion (€22 billion) in 2018 and is gaining high popularity due to the integration of these technologies across various manufacturing sectors. The countries including the UK, Germany, France, etc. are witnessing rapid technical development in manufacturing & supply chain industries due to high labor costs in the region. The European countries have a robust automotive production industry, which is developing due to increasing passenger & luxury car demand.

As a result, the companies are developing intelligent operational capabilities, developing the smart factory market. Additionally, the government & private company initiatives in Europe for developing smart factories and boosting manufacturing through Industry 4.0 are majorly driving the industry growth.

‘The key companies present in the smart factory market are Rockwell Automation, Schneider Electric, ABB, General Electric, Fanuc, Robert Bosch GmbH, Siemens AG, Honeywell International Inc., and Emerson Electric. The players are continuously developing new software & service technologies for supporting the robust manufacturing sector across the globe.

The companies are making high investments in R&D activities that aid the development of new technologies for catering to the demand for industrial automation from the application industries. The market players are also expanding their focus on Industrial IoT technologies by making several investments. For instance, in December 2018, General Electric announced that it invested US$1.2 billion for establishing an IIoT software company to serve industrial customers.