How Fine Aggregate Affects Mix Design of Concrete?

Fine aggregate is on of the major constituents of concrete which can influence concrete mix design substantially. Various factors such as fine aggregate fineness modulus, moisture content, specific gravity, and silt content affect the mix proportions of concrete. Fineness modulus specifies how much fine aggregate is required in a given mix design.

Fine aggregate moisture content influences the mix proportion substantially. It specifies the amount of water that may be added to subtracted to the mixture. Mix design of concrete cannot be carried out without specific gravity of fine aggregate, and higher specific gravity produced stronger concrete. Finally, the presence of silt in sand would increase water demand in concrete mixture and may reduce concrete strength.

1. Fineness Modulus

It is one of the factors that influence concrete mix design since it controls the proportion of sand in concrete mixture. The overall fineness of sand is given by factor called fineness modulus, and it is found by sieve analysis based on ASTM C 33/ M33 specifications or any other applicable standards. The fineness modulus of sand varies from 2 to 4.

2. Moisture Content

Moisture content of fine aggregate is a crucial factor while suitable water to cementitious material ratio are established. It is undeniable that all aggregates contain some moisture based on moisture condition of the storage area and particle porosity.

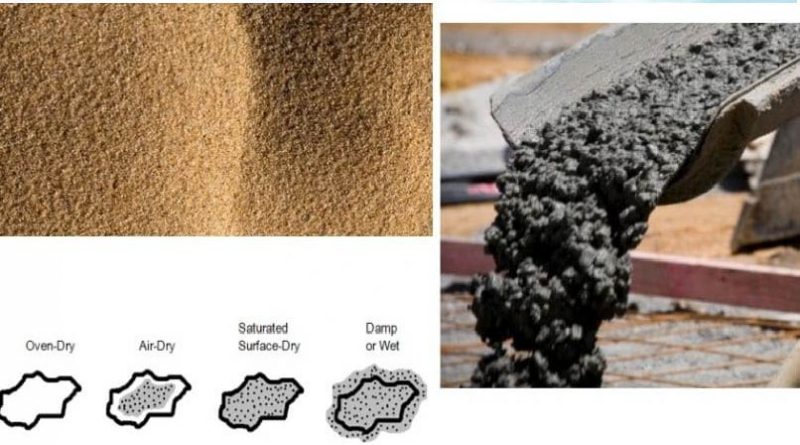

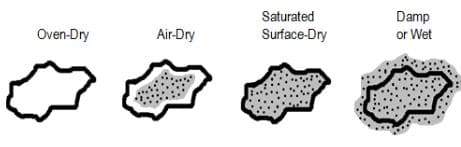

Fine aggregate can be found in four different moisture conditions namely: oven-dry (OD), air-dry (AD), saturated-surface dry (SSD) and wet. Only OD and SSD correspond to a specific moisture state and can be used as reference states for calculating moisture content.

Frequently, fine aggregate is in wet condition with surface moisture up to five percent. This is known as bulking and can cause significant errors in proportioning volume. It is required to estimate aggregate water absorption in order to calculate the amount of water that aggregate would add or subtract to the paste.

3. Specific Gravity

Specific gravity is the ratio of solid density of sand particles to the density of water, and it can be computed by following test method and procedures provided in ASTM C128-15. Bulk specific gravity, which is measure of volume occupied in concrete including solid aggregate particles and voids between them, is required for proportioning of concrete mixture.

Higher the specific gravity heavier is the sand particles and higher is the density of concrete. In contrary, a lower specific gravity of sand will result in lower density of concrete. The specific gravity of fine aggregates found in Pune region varies from 2.6 to 2.8.

4. Silt Content

This is found by wet-sieving of sand and material passing 75-micron sieve is classified as silt. This silt affects the workability of concrete, results in higher water/cement ratio and lower strength. The upper limit for 75-micron sieve in case of sand is 3% by weight. This limit has however been extended to 15% in case of crushed sand in IS 383 – 1970 Table 1.

Source: theconstructor.org