The Benefits of Using Steel in Construction

The trade of steel is an important part of the global economy, with about five million people involved in making this metal worldwide and a further million people employed in service centers, galvanizing plants and trading. Every year the world produces about 1,600 million tons of crude steel – the equivalent weight of about 160,000 Eiffel Towers.

It’s also of vital important to the US. The country is the world’s top importer of steel – with $29 billion of the material shipped into the United States in 2017 alone – and so it’s easy to see why politicians focus on this.

So, what underpins these big numbers? As CNN notes, roughly half of all steel is used in buildings and infrastructure, helping to construct frames and pipes in everything from skyscrapers to homes and bridges. The next most common use is mechanical equipment (16%) followed by automotive (13%), metal products (11%), shipping rail and transport (5%), electrical equipment (3%) and domestic appliances (2%).

As we can see, therefore, construction is by far the most common use for steel. So why is it so popular in this sector?

It’s adaptable

As you can see from the long list of uses above, steel can be effectively used in a number of different practical scenarios. Steel wall frames can be easily adapted if plans change or a building needs expansion or alteration.

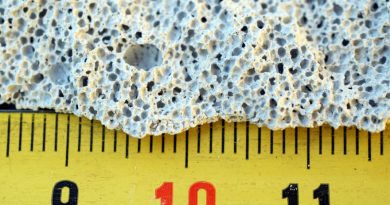

It can help to create the look you want

If appearance and beauty matter to you then steel is a good choice. Want a wide-open spacious office free from columns? That can easily be delivered with a steel frame – making it ideal for everything from agricultural buildings to garages and indoor arenas.

It’s lightweight

You might not expect it, but steel is actually lighter than wood. Not side by side in a 2×4 of course, but it is used as a beam in a structure. This can help to reduce transport costs, cutting the amount of weight of material you need to ship to a construction site.

It’s strong

If you need a material that can withstand the elements – be it wind, rain, sun or snow – then you need steel. Using steel also means you have no worries when it comes to mould, mildew and fungi and it is more resistant to fire and doesn’t warp, distort, buckle or splinter. This durability makes it cost effective too, as it’ll stand the test of time.

It’s ductile

Steel might be strong, but that doesn’t mean it isn’t flexible. The ductility of this metal means that it can be rolled or cut up into any shape or size that you require.

It aids quick construction

Many steel parts are pre-engineered which means they are ready to go straight into a construction once they are delivered, perfect to help speed up projects.

It’s environmentally friendly

Businesses across the globe are becoming more eco-friendly. This is reflected in the construction industry and the practices that are used. Steel is made from recycled materials and it can be recycled when you’re finished with it too – making it an ideal choice for people keen to showcase their green credentials while engaged in construction projects. With 80 million tons of steel recycled every year, it’s said to be the world’s most recycled product.

Source: blog.constructionmarketingassociation.org